I. Gambaran Umum

Sensor Gas/VOC Kabèh yaiku sensor gas polimer wujud padhet sing dirancang kanggo ngukur sacara komprehensif macem-macem senyawa organik volatil (VOC) lan gas-gas beracun. Sensor iki operasi adhedhasar prinsip elektrokimia polimer wujud padhet, sing analog karo mekanisme réaksi elektrokimia fasa cair tradisional. Komponen intine diprodhuksi nganggo proses print, sing nambah konsistensi produk lan hasil produksi kanthi signifikan.

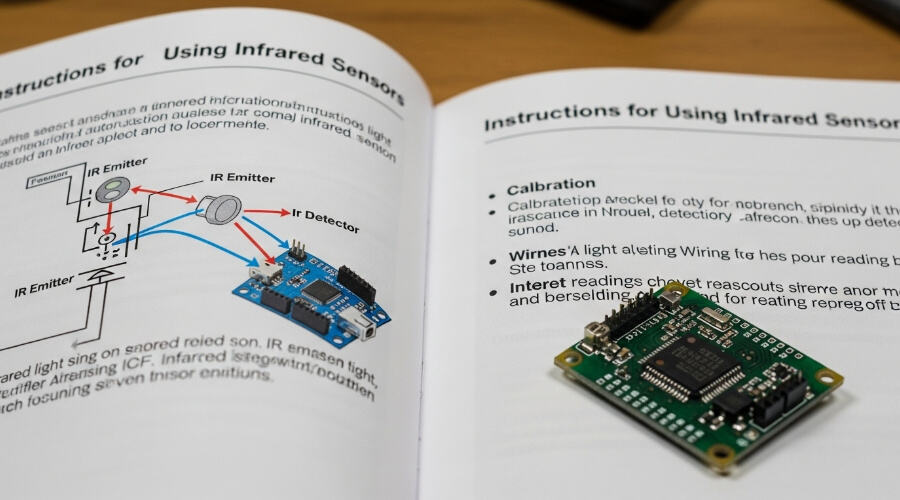

Senser kasebut dumadi saka telung éléktroda: SE (Sensing Electrode) minangka éléktroda kerja, CE (Counter Electrode) minangka éléktroda balikan, lan RE (Reference Electrode) minangka éléktroda tambahan. Éléktroda referensi njaga potensial sing stabil lan disambungake menyang éléktroda kerja, saengga bisa ngukur kanthi tepat potensial éléktroda kerja lan owah-owahane.

Senser iki biasane operasi ing loro modus aplikasi utama:

1. Pengukuran Komprehensif : Iki mengaruhi ngukur jumlah total gas beracun akeh lan senyawa organik volatil (VOCs). Konsentrasi gas sing dideteksi déning senser nglambangake konsentrasi total komprehensif, lan ora bisa mbedakake nilai konsentrasi saben gas dhéwé.

2. Pengukuran Gas Tunggal : Iki kalebu ngukur konsentrasi gas target tunggal ing lingkungan tunggal (yaiku, mung ana siji gas ing lingkungan kasebut ing wektu sing padha).

IV. Kalibrasi

1.Metode Kalibrasi Pengukuran Lengkap --Ketika sensor digunakake kanggo pengukuran lengkap, gas kalibrasi kudu dipilih miturut gas spesifik sing arep diukur lan tujuan tes.

1.1 Tentokake gas kanthi konsentrasi paling dhuwur ing lingkungan gas campuran, lan gunakake gas standar saka gas iki kanggo mengkalibrasi sensor.

1.2 Tentokake gas kanthi tingkat bebaya paling dhuwur ing lingkungan gas campuran, lan gunakake gas standar saka gas iki kanggo mengkalibrasi sensor.

1.3 Yen ana gas target sing ditentukan kanggo diukur miturut syarat pengukuran, gunakake gas standar saka gas sing ditentukan kanggo mengkalibrasi sensor.

1.4 Ketika syarat-syarat ing ndhuwur ora bisa ditentokake, gas karbon monoksida bisa digunakake kanggo kalibrasi nganggo metode rasio 1:2 supaya mesthekake sensitivitas tanggapan marang mayoritas gas.

2.Metode Kalibrasi Pengukuran Tunggal

Ketika sensor digunakake kanggo pengukuran tunggal, kalibrasi nganggo konsentrasi gas standar saka gas sing arep diukur.

Kondisi Reaksi Normal Etanol ing Kabeh Sensor Gas -Nalika gas etanol (alkohol) mlebu sensor, kedadeyan réaksi kimia ing Elektroda kerja SE . Elektroda lawan CE lan Elektroda acuan RE aja nganti kena gas etanol (alkohol). Nalika jumlah etanol sing pas mlebu, kabeh gas bereaksi sacara lengkap ing elektroda kerja SE. Ing wektu iki, kahanan pangukuran sensor paling optimal. aja nganti kena gas etanol (alkohol). Nalika jumlah etanol sing pas mlebu, kabeh gas bereaksi sacara lengkap ing elektroda kerja SE. Ing wektu iki, kahanan pangukuran sensor paling optimal. Reaksi etanol ing sensor reaksi positif reaksi positif , lan sinyal metune yaiku nilai positif. , lan sinyal metune yaiku nilai positif.

Kondisi Reaksi Etanol Konsentrasi Tinggi ing Sensor Gas Kabeh -Nalika gas etanol konsentrasi dhuwur utawa gas mampet diarahake langsung menyang inlet udara, akeh banget gas etanol sing mlebu ing sensor. Elektroda kerja SE ora bisa ngrampungake reaksi ing wektu cendhak, utawa amarga tekanan, gas bisa mlebu ing elektroda referensi RE. Iki nyebabake sinyal owah saka positif dadi negatif. Yen konsentrasi on ngluwihi 1500ppm lan gas terus diintroduksi selama 2 jam , sensor mbutuhake paling sethithik 10 jam wektu pulih sadurunge pangukuran normal bisa diwiwiti maneh kanggo kaping pindho.

I yen pangukuran khusus kanggo ethanol (alkohol), disarankan nggunakake sensor alkohol khusus. Yen tetep dibutuhake pangukuran komprehensif lan deteksi alkohol sesekaran, gunakake gas ethanol kanthi konsentrasi kurang saka 100ppm kanggo kalibrasi, kanthi laju aliran 300ml/min lan suplai gas terus-terusan maksimal 3 menit . Saos kalibrasi, hindharé ngarahké gas kanthi laju aliran langsung menyang inlet udara; gunakna sisi (sudut 90 derajat marang inlet udara) supaya sensor bisa ngukur ing kahanan difusif lan nyegah aliran (dampak aliran). Kanggo aplikasi khusus, mangga konsultasi dhéwé karo perusahaan kita.

Kasus Pengujiyan/Kalibrasi Non-Konvensional -Nalika gas standar etanol ora kasedhiya kanggo pangujian/kalibrasi sensor lan alkohol cair kudu digunakaké, catetan sing sabanjuré: Nalika kain utawa bahan liya direndhem alkohol cair banjur dilebokaké ing kantong/wadah kedap udara saka plastik utawa kaca, konsentrasi ing ruwang tertutup ing suhu kamar (25°C) bisa langsung menguap nganti 600,000ppm , lan konsentrasi uap bakal luwih dhuwur ing suhu ndhuwur 25°C. Mulane, aja langsung nempatake kain utawa bahan sing dibasahi alkohol kanggo senso r tes. Yen metode iki kudu digunakake kanggo kalibrasi relatif/tes, encerke gas sadurunge ngukur: Siyapke suntikan, kantong wadah kedap udara, lan itung volume kantong/wadah kedap udara kasebut. Tentuke rasio pengenceran adhedhasar konsentrasi target (100ppm utawa kurang). Gunakake suntikan kanggo narik volume gas sing wis diitung saka kantong uap 600,000ppm lan suntikake menyang kantong/wadah kedap udara liyane kanggo diencerake. Lebokake sensor sing arep diuji menyang kantong/wadah pengenceran mengarep, lan posisine miturut gravitasi spesifik gas etanol marang udara.

Berita Terbaru

Berita Terbaru2025-11-21

2025-11-13

2025-11-13

2025-10-29

2025-10-22

2025-10-28